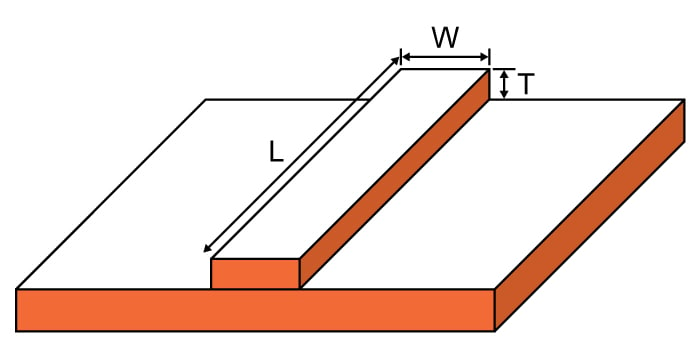

The capacity of the current passing through the copper traces mainly defines the width of the copper trace.

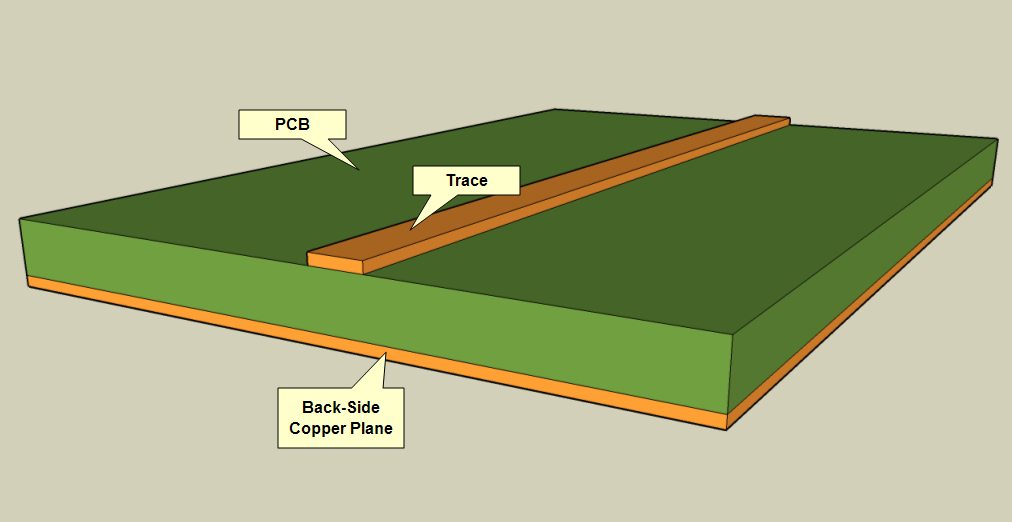

They come with varying thickness depending on the applications they are used in. These traces are conductive and electrically connect different electrical components on the board. On top of the substrate is the copper trace. This substrate material is non-conductive and provides the core strength and rigidity to the board. And most common fiberglass is composed of FR4 material. The base of the PCB is made of a substrate which is fiberglass.

#Pcb trace width calculation how to

How to Calculate PCB Trace Widthīefore we move further and discuss how to calculate PCB trace width, let’s first define what PCB traces are, and why they are used. Let’s dive in and elaborate on how to calculate the PCB trace width. That was all the little intro about printed circuit boards.

Thanks to technology… nowadays, electrical devices are more sophisticated, economical and are capable of performing more functions than their predecessors. Needless to say, PCB has revolutionized the modern electronics that are precise and compact and cover less space compared to devices where wire wrap and point to point construction is used. On the non-conductive side of the board copper traces electrically connect these components.Įarlier end-to-end wiring was used in place of PCB boards but now it’s become obsolete. Different electrical components are placed on the non-conductive substrate which are soldered from the other side of the board. The PCB (printed circuit board) is a mechanical layout that electrically connects different components on the board using conductive copper traces that maintained current throughout the circuit board.

In this post today, I’ll discuss how to calculate PCB trace width?

0 kommentar(er)

0 kommentar(er)